Nærø

Acoustic batt

Nærø

Acoustic batt

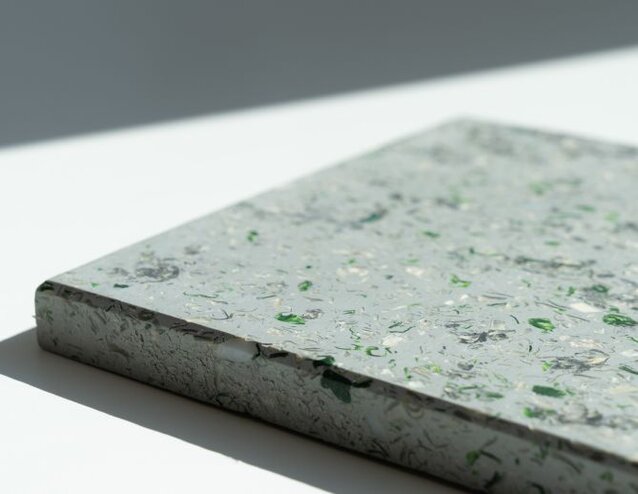

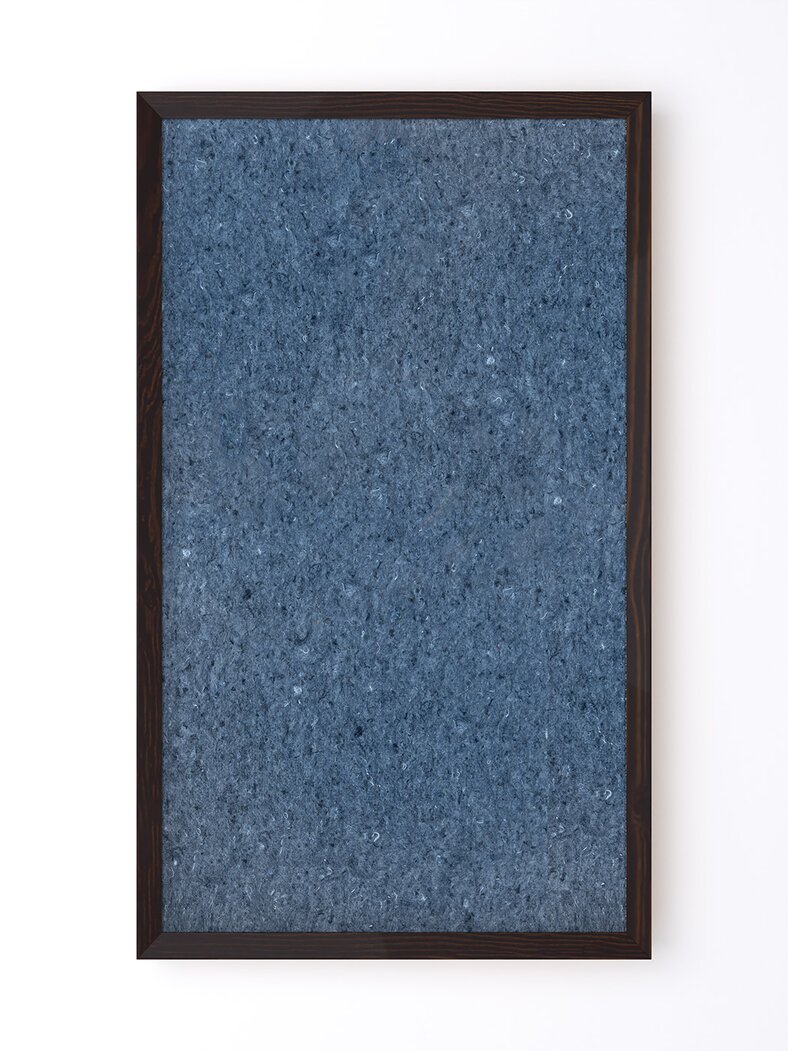

Nærø is an acoustic batt made from post-consumer and post-industrial textile waste. Our Nærø acoustic batts are used in most of our acoustic panel products, but they are also available for purchase as standalone batts. They come in a variety of colours and sizes.

Nærø is an acoustic batt made from post-consumer and post-industrial textile waste. Our Nærø acoustic batts are used in most of our acoustic panel products, but they are also available for purchase as standalone batts. They come in a variety of colours and sizes.

Nærø Batt: Dark Grey

Your environmental impact:

Product | Acoustic batts |

Source | Waste textiles |

Material | Primarily cotton and polyester |

Application | Acoustic absorption |

Thickness | 50mm |

Width | 560mm |

Weight | 80 kg/m3 |

Height | 960mm |

Absorption | Class B |

Made in | Denmark |

Nærø delivered at scale

Bella the Brewery / Martha Christensens Vej 10, 2300 Copenhagen

Novo Nordisk Hub 1 / Copenhagen, Denmark

Novo Nordisk Bagsværd / Copenhagen, Denmark

Bronsø - Wooden facade cladding