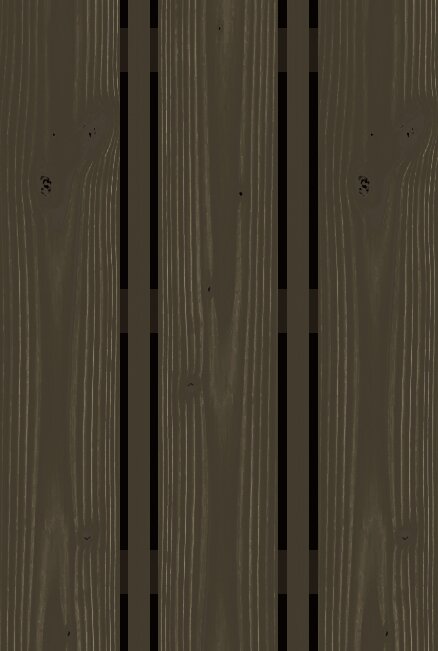

Flarø Douglas

Acoustic wall panel

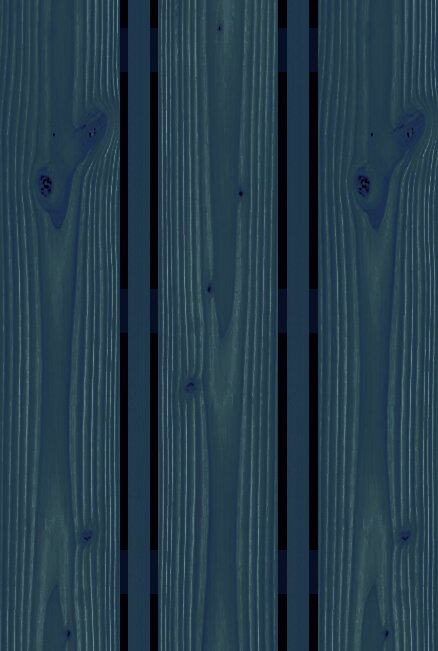

Flarø Douglas

Acoustic wall panel

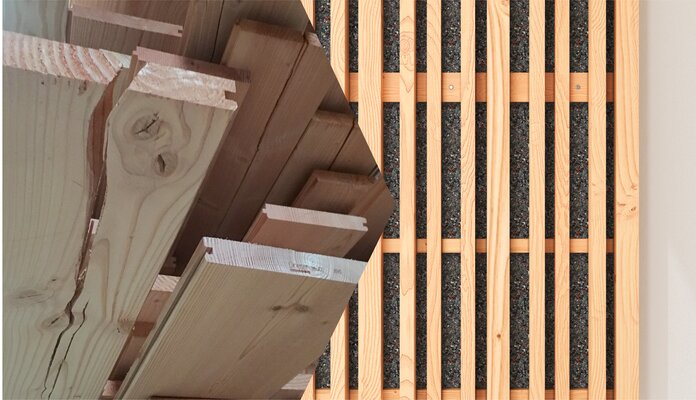

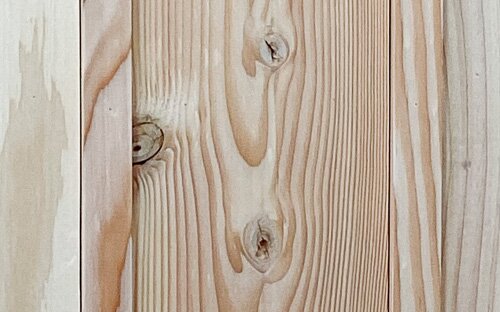

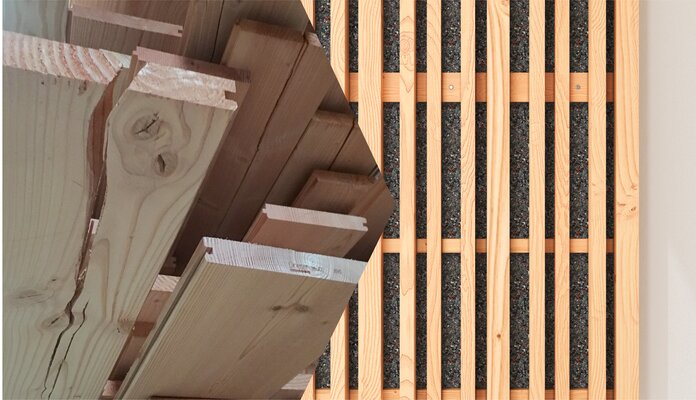

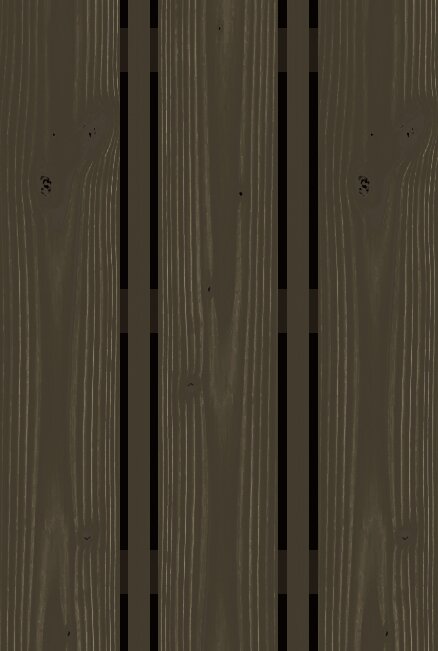

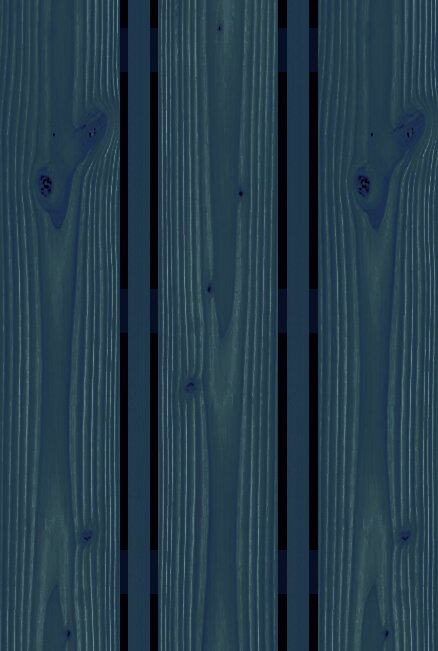

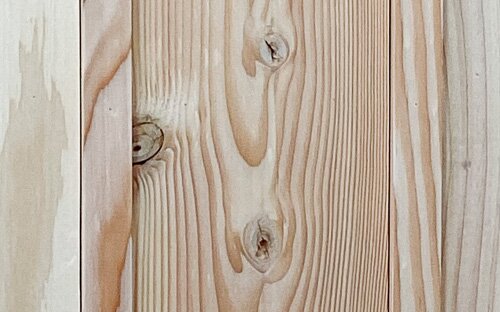

Flarø Douglas is a full wall indoor acoustic paneling, made from discarded material from regular production. It is combined with our Nærø acoustic batts made from post-consumer textile waste. Flarø Douglas comes in various wood and textile finishes.

Flarø Douglas is a full wall indoor acoustic paneling, made from discarded material from regular production. It is combined with our Nærø acoustic batts made from post-consumer textile waste. Flarø Douglas comes in various wood and textile finishes.

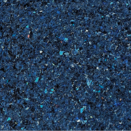

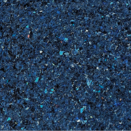

Nærø batt:: Dark Grey

Your environmental impact:

Product | Full wall acoustic panelling for indoor sound absorption |

Source | Discarded material from regular production |

Wood and finish | Douglas, waxed |

Thickness | 54 mm (without textile absorbent) |

Height | 2455 (or 2755) mm |

Width | 490 mm |

Weight / Density | 2455mm/490mm: ~15,8 kg/unit with felt (Nærø)

2755mm/490mm: ~17,7 kg/unit with felt (Nærø)

Pr. m2: ~13,1 kg/m2 with felt. |

Installation | Front facing screws, through horizontal slats |

Sound absorption | Class A, with 50 mm absorbent (expected) |

Delivery | 6-8 weeks generally, subject to change |

In collaboration with | |

Made in | Denmark |

"I am made from discarded wood then turned into acoustic panels"

Flarø Douglas delivered at scale

Daarbak Design Showrooms / Roskilde & Vejle, Denmark

Bella the Brewery / Copenhagen, Denmark

"I am made from discarded wood "

9.1 kg waste saved*

1.9 kg CO2eq footprint*

*Per m2 based on internal LCA calculations for phases A1-A3

1 Collection

2 Milling

3 Profiling

4 Manufacturing

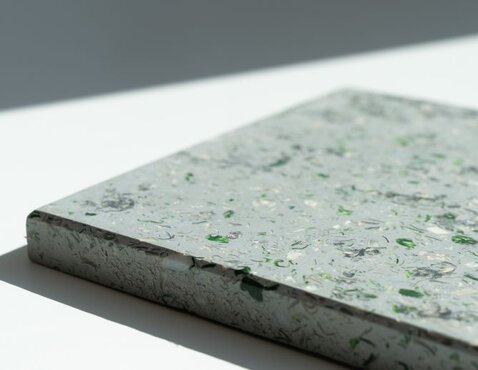

We use our Nærø batts in the Flarø Douglas panels, the batts are available in varying shades of grey, blue and white, which are determined by the clothes it is produced from. We can never ensure an exact repetition of a specific nuance, from batch to batch, since our input material will always vary slightly. However, this just means that your batch is unique to your project!

Class | B |

Weighted absorption coeffient | 0.85 |

CE Mark | Coming |

EPD | Coming |

Does Flarø Douglas contain any hazardous materials?

Jesper Wøldike Brandt / CSO

+45 40 33 43 11

jesper@again.dk

Christian Steen Wittrup / Market & External Relations Director

+45 24 90 80 10

christian@again.dk

Product | Full wall acoustic panelling for indoor sound absorption |

Source | Discarded material from regular production |

Wood and finish | Douglas, waxed |

Thickness | 54 mm (without textile absorbent) |

Height | 2455 (or 2755) mm |

Width | 490 mm |

Weight / Density | 2455mm/490mm: ~15,8 kg/unit with felt (Nærø)

2755mm/490mm: ~17,7 kg/unit with felt (Nærø)

Pr. m2: ~13,1 kg/m2 with felt. |

Installation | Front facing screws, through horizontal slats |

Sound absorption | Class A, with 50 mm absorbent (expected) |

Delivery | 6-8 weeks generally, subject to change |

In collaboration with | |

Made in | Denmark |

"I am made from discarded wood then turned into acoustic panels"

Flarø Douglas delivered at scale

Daarbak Design Showrooms / Roskilde & Vejle, Denmark

Bella the Brewery / Copenhagen, Denmark

"I am made from discarded wood "

9.1 kg waste saved*

1.9 kg CO2eq footprint*

*Per m2 based on internal LCA calculations for phases A1-A3

1 Collection

2 Milling

3 Profiling

4 Manufacturing

We use our Nærø batts in the Flarø Douglas panels, the batts are available in varying shades of grey, blue and white, which are determined by the clothes it is produced from. We can never ensure an exact repetition of a specific nuance, from batch to batch, since our input material will always vary slightly. However, this just means that your batch is unique to your project!

Class | B |

Weighted absorption coeffient | 0.85 |

CE Mark | Coming |

EPD | Coming |

Does Flarø Douglas contain any hazardous materials?

Jesper Wøldike Brandt / CSO

+45 40 33 43 11

jesper@again.dk

Christian Steen Wittrup / Market & External Relations Director

+45 24 90 80 10

christian@again.dk

Bronsø - Wooden facade cladding